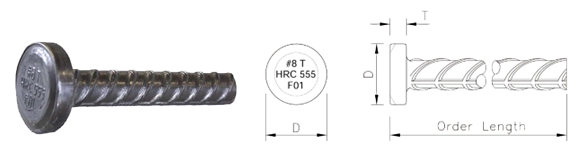

HRC 555 Headed Rebar

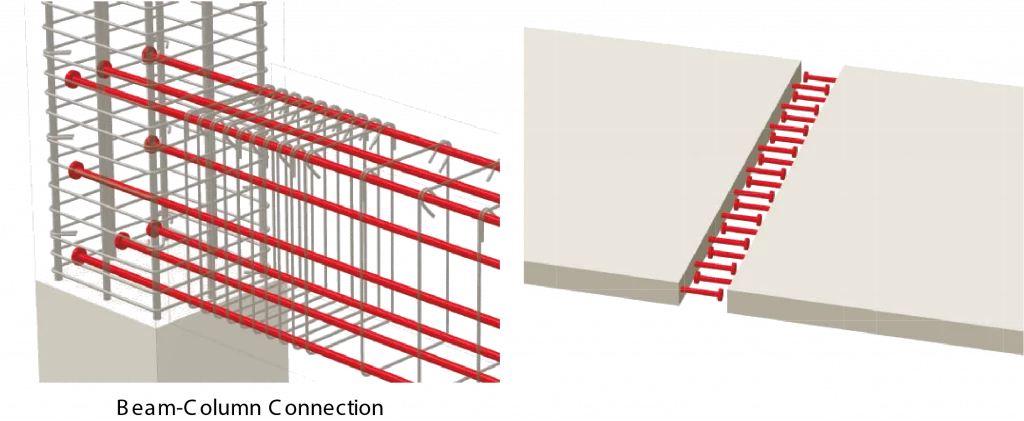

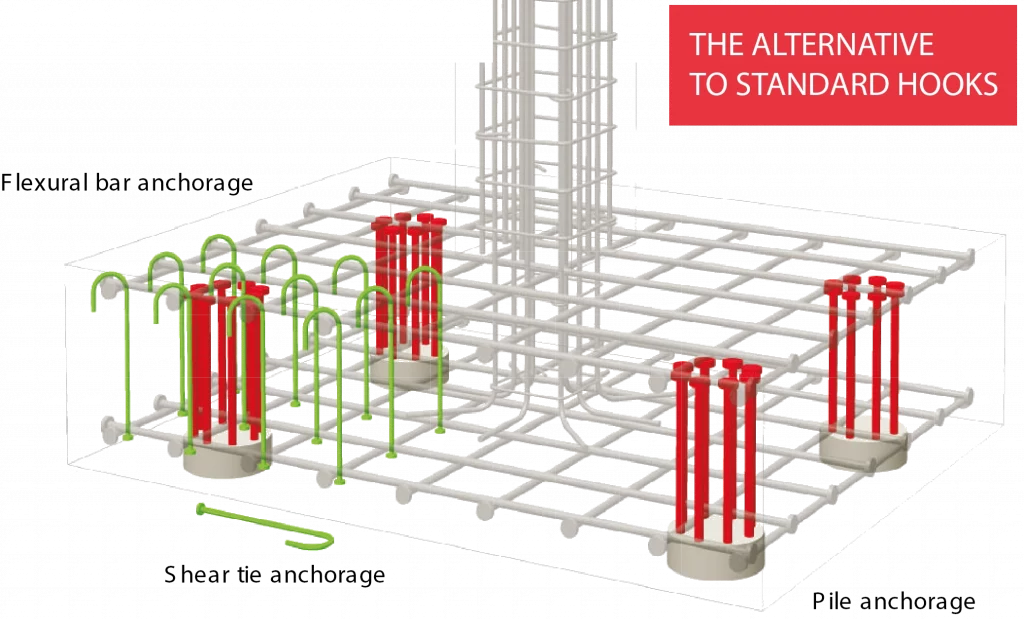

HRC 555 headed reinforcing bar is a deformed or plain steel bar with a head attached to one or both ends. HRC 555 reduces anchorage length, congestion, and construction time while providing superior performance. A great alternative to standard hooks throughout your concrete structure, from pile anchorage to beam/column joints.

Research has shown headed lap splices are very effective for closure pours and according the Section 12.6 of ACI 318-08 the HRC 555 Series headed bars have the shortest required development length compared to standard hooks or straight bars. Great for closure pours and other locations not permitting the length of conventional lap splices. The use of Headed Reinforcement improves the form, fit and functional performance of reinforced concrete structures at a low cost. The concrete also benefits because adequate space for pouring and vibrating will give better concrete consolidation. Reduced congestion and the ease of placing Headed Reinforcement will improve constructability and speed up the project.

HRC 555 Headed Rebar

Benefits

• Simplify reinforcing details

• Reduce congestion

• Improve field tolerances

• Speed up installation.

T-head rebars

T-head rebars (also known as “headed reinforcing bars”) are reinforcing steel bars for concrete structures, that are equipped with a device for mechanical anchorage in one or both ends. The anchorage device (the “head”) often has the shape of a plate, that makes the end look like the letter “T”. Therefore, the term “T-head rebar” is used.

Headed reinforcing bars are used in the same way as common reinforcing bars, with the “head” providing the anchorage of the bar. This type of anchorage is an alternative to anchorage by rebar bends or hooks.

The anchorage capacity provided by the T-head depends on three factors:

- Bearing area of the head

- Stiffness of the head

- Strength of the head-to-bar connection

History of T-head rebar

Anchor plates have been used for anchorage of rods in structures for centuries. The use of the same principle for rebar is a consequence of the development of reinforced concrete. Early examples of headed bars can be found in publications printed more than 100 years ago.

The newer development of headed bars was triggered by more demanding constructions, as offshore concrete structures and the evolution of earthquake engineering that required high structural performance. The use of headed bars in concrete design has created the need for guidelines in the design codes for structural concrete and standardized specifications of the product.

Advantages offered by HRC T-head rebars

ultimate performance of HRC products should be a standard requirement in your design. HRC products give you advantages in structural performance, installation savings and benefits in construction progress and economy.

For the designer

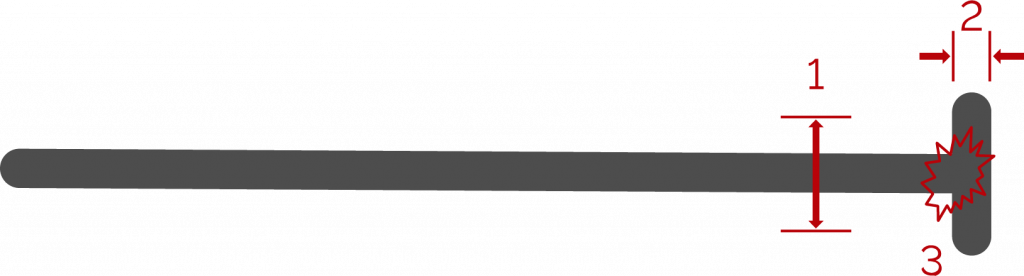

- Development of the actual (real) tensile strength of the rebar — just in the T-head

- The full ductility of the rebar is developed —the very basis for a robust structure

- Anchorage capacity is independent of bond between rebar and surrounding concrete – beneficial in concrete with low bond properties, such as lightweight aggregate concrete

- Reduces congestion by avoiding anchorage bends and hooks

- Possible to use fewer larger bars (standard up to 40mm)

- Excellent confinement effect as a result of the stiff anchorage by the T-head

- Very slim heads (thickness of head plate) allow high flexibility in the design

- Can easily be combined with any other HRC Product series at the other rebar end

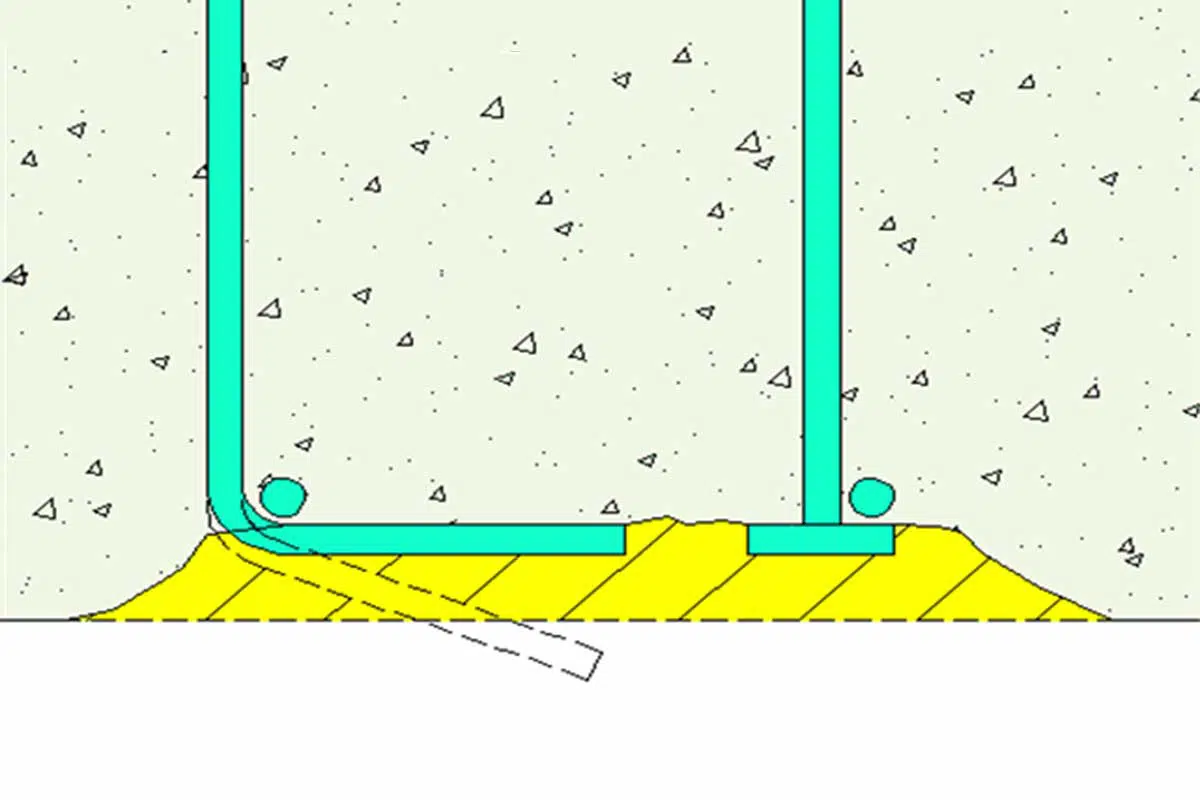

For the construction site

- Fast installation of headed bars!

- Reduced congestion and improved casting conditions

- Bars without bends and hooks are easier and safer to handle than bend bars

- The absence of bends improves access to the workplace and leads to safer, faster and more precise work

The concentrated and stiff anchorage properties of HRC-headed bars are not dependent on a certain bond length to develop the full tensile strength of the reinforcement in concrete; 100 % anchorage by the head alone.

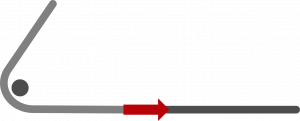

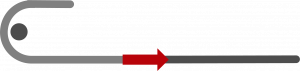

Straight anchorage length

Anchiore Bend

Anchorage by hook

Mechanical anchorage: HRC T-head

Improved robustness at overload and accidental conditions

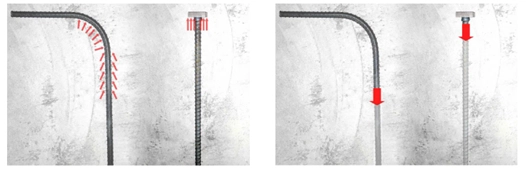

Pictures of situation after test of CIDH pile Supported Footings (University of California, San Diego).

Conventional stirrups: straightened and pushing out the concrete cover leads to loss of rebar anchorage.

Model of test: Left conventional stirrups and T-headed transverse reinforcement to the right.

T-headed transverse reinforcement: cracking of concrete surface only, while rebar anchorage stay intact